5 golden rules to cut glass tiles correctly by using a diamond blade on an electric wet saw

Having a good diamond blade for glass tiles is not enough to get a perfect cut on glass tiles or glass mosaic, either glossy or matte. It really is necessary to follow some small but important steps that will help you improve the finished cut and avoid chipping or damage that can be visible on the painted surface of the glass tile.

Here are the top five tips that are recommended by professional tilers who are specialists in laying glass tiles to those who are about to use this material for the first time.

- Use a specific glass blade to cut glass tiles that is high quality and is made with a very fine and uniform diamond grain;

- Thoroughly clean the surface of the electric tile saw on which the glass tile or glass mosaic will be placed. Even a small grain of sand or piece of glass might be enough to prevent the diamond blade from operating correctly. It could even damage the painted side of the glass tile. This tip gains importance in the case when you use a water electric tile cutter with a stable disk, and for this reason, you need to slide the tiles on the support surface. The support surface can be easily cleaned with plain water.

- Revive the blade before cutting Many diamond blades, unless brand new, do not have a ready-to-cut diamond edge. In this case it is advisable to increase the cutting capacity of the blade by reviving (clearing) the cutting edge of the diamond crown. It is easy to dress the cutting edge by using a special white fine-grained abrasive stone. Attention! Do not use concrete blocks to sharpen blades which are meant to cut glass tiles, you could damage the blade irreparably. A well sharpened revived disk will increase the speed of cut and will reduce cutting vibrations considerably.

- Use plenty of water when cutting glass tiles or glass mosaic If you have a water cutter with the possibility to regulate the water flow that goes on to the disc, make sure that the valve is adjusted to the maximum flow. Superheated glass tends to crack and chip easily so you need to use a lot of water to cool down both the diamond blade and the glass tile or glass mosaic.

- Make sure that the cutting process is not too slow. If the glass blade you are using is of high quality, it will be possible to cut glass tiles very quickly, thus reducing both the vibration and the risk of chipping. If you have a glass blade of medium-low quality, the only thing that can be suggested is the use of a lot of water although the result still won’t be perfect. Once you have completed the cutting phase, never forget that you are dealing with glass tiles and handle them with great care, paying special attention to the corners, which are particularly fragile and can be sharp. Given the high cost of glass tiles and glass mosaic, when working in a bathroom or kitchen, it is always good procedure to use a professional diamond blade. If you don’t you risk spending a fair amount of money to buy the material, you may end up with a poor result due the inappropriate cutting and laying procedure.

CLICK HERE TO DISCOVER A MANUAL TILE CUTTER ABLE TO CUT GLASS AND PORCELAIN

MAIN PROBLEMS ARISING DURING GLASS TILES CUTTING

The photo above, sent by a reader of our blog (from Florida – U.S.A.), shows one of the main problems arising from using the wrong techniques and products.

Along the edge of the glass tiles in the shower cubicle it is possible to see several large chips on the painted surface of the glass tiles, leading to an unacceptable aesthetic result.

The client in this specific case complained to the building company and obtained a full refit of the shower cubicle. Needless to say that no building company would be happy to pay for the tilers work twice!

So, it is clear that one of the biggest challenges that tilers and installers are facing everyday is cutting glass tiles or mosaics. These materials are very fragile. Infact, manual or dry cutting always present a high risk of cracking.

Last but not least, for decorative reasons, some glass tiles and mosaics are back-painted. During the splitting process this paint can be damaged causing unaesthetic visible chips.

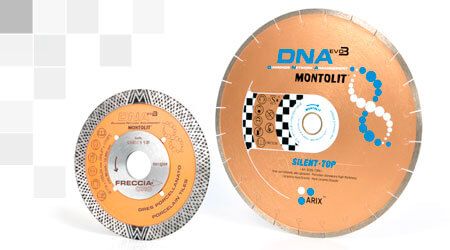

In order to properly work with these materials, it is essential to use the right tools as well as the correct cutting technique. This is the reason why Montolit invented Cermond CPV100 (4”), a small diamond blade for grinder specifically designed to obtain almost factory edge cutting any kind of glass tiles or mosaic.

Why Cermond CPV100 (4”) by Montolit is the ideal solution for glass tiles cutting

First of all, its delicate touch allows to cut very thin and fragile glass tiles.

This blade is equipped with a special continuous rim with fine grane diamonds and a copper-made body. These technical characteristics avoid chipping also on thick glass tiles.

Like all the top blades on the market it is meant for wet use only and it is not fast.

Discover more about Cermond CPV100 (4”)

Three useful hints while cutting glass tiles with grinders

- On back-painted glass tiles it is recommended to cut the tile upside down in order to prevent chipping the back.

- It is very important to keep the Montolit CPV glass blade very sharp. In order to do this, we recommend the use of a dressing stone with micro grains so that it is able to clean the small diamonds very well.

- Abundant use of water and not forcing are the keys to get the best performance out of a glass blade.

YOU MAY BE ALSO INTEREST IN HOW TO CUT GLASS WITH A MANUAL TILE CUTTER

Created by: Develed Digital Marketing

Copyright 2022 Brevetti Montolit S.p.A. - VAT number IT00713300127 - R.E.A. VA151380 - Social Capital fully paid €500.000,00 - Registered office address: Via Turconi 25 – Cantello (VA) - PEC certificata@pec.montolit.it

Digital Marketing by Develed Sagl