How to cut large format porcelain tiles?

Bigger tiles, better known these days as Large Format Tiles, are penetrating the market and creating a big impact.

It has taken producers a few years of research and development with prototypes, trying to get them right, and now it seems that most of the major manufacturers are producing quality ceramic and porcelain tiles in large formats with thicknesses from 3 mm upwards.

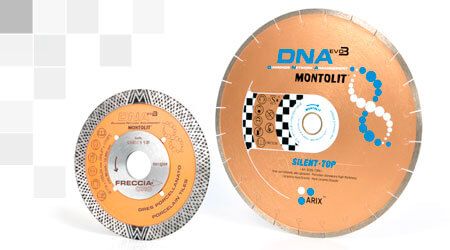

Tiles of this kind, besides being very difficult to handle, are extremely complex to cut and drill in a manner which produces clean edges and no chipping. To do that you need the right porcelain slab cutting tools.

The biggest problem is not the constituent material of the tile, which, these days is generally far superior than in the past, but the fragility of the tile as a whole.

The length is one of the most critical points about cutting large tiles.

When we speak about large format porcelain tile cutter, for example, the difficulty lies in making an incision that will help to propagate the crack along the entire length of the tile when pressure is applied for splitting.

This is particularly difficult on tiles that are 1.5 m long if not more in the case of the Kerlite ‘Cotto D’Este’ or similar tiles made of Granite Fiandre.

So often, when Drilling holes for amenities, another problem arises that is linked to the excessive length of these types of tiles.

So which is the best way to cut large format tile?

If the hole is not created in the correct workman like manner – that is by producing a “clean” round hole which is continuous and complete – the tile may crack or split completely during handling.

Also in this case, it is very dangerous to make square holes before the tile is laid because, from the square corners of the hole, cracks could start to appear caused by the tile layer creating unsolicited twist to the tile when moving it around or when actually laying it.

Now we must emphasize that for large format tiles the problems we have spoken about are very pronounced and require special attention because there is a high risk of breaking tiles that are costing a few hundred euros.

Given the characteristics of these big tiles, only a few expert team of pose can made a good installation to achieve a ‘state of art’ finish with this type of product.

Please realize that the market is going in this direction being driven mainly by Architects, surveyors and interior designers who are specifying this product more and more.

You might also like to read and study the following post that deals with the use of tiling tools specifically designed for the cutting and drilling of large format tiles.

Tile cutter 155P2, for 155 cm tiles presented at Cersaie fair 2010

Montolit Masterpiuma 125P2 Tile Cutter

Please view our new high resolution video that illustrates a step by step guide on how to use the new manual tile cutter 155P2 with its ergonomic accessory stand called the ‘Vertigo’.

In a first phase, the video shows how to cut large format porcelain tiles with a tile cutter in the standard mode of use – working on the floor. This mode of cutting is the most widespread but can be more damaging and strenuous to the operator.

So much so that in time this way of working may give rise to physical problems due to working in a difficult and incorrect posture. Back and knees are the most stressed parts.

In addition, cutting large format porcelain tiles (90, 100, 120 cm), creates a technical problem linked to the incision.

This problem occurs both when working on the ground or on a raised work table where the extreme length of the tile forces the fitter to start the incision which then, unable to get right to the end of the tile, causes problems to the individual for obvious reasons related to the length of the arm. This in turn stops the incision process because one has to reposition the body and then return to finish the scribe.

Basically the incision is not continuous which results in an interrupted exercise that varies the etching pressure quite a lot in different parts of the tile.

The irregularity of a short ‘jerky’ incision action on tiles creates an incision line that is not of continuous pressure, or depth, thus leaving places on the tile not scribed. This will then cause the tile to veer off line when the pressure is applied to split tile after incision.

In order to avoid this problem on very long and expensive tiles our tech department has studied how to overcome this problem and developed the ‘Vertigo’ stand as an accessory to mount the cutter upon.

The Vertigo holds the Tile Cutter in a near vertical position and by using this accessory the tiler can make the incision in a convenient ergonomic way, without interruption, with the added advantage of applying constant pressure from start to finish of the tile which greatly reduces the risk of breakage.

ALSO: – working with the cutter in a near vertical position has two other big advantages:

It significantly reduces back and knee problems, and will greatly reduce the footprint of the cutter in work-room, leaving space for handling other equipment and materials more safely.

Specifically shown in the video is the vertical cutting of a very thick tile.

In this case, after the incision, to facilitate the easier splitting of this tile another accessory is used called “Big Foot“. This is a special accessory for use on thick tiles. The pressure pad of this item is wide and thick and is made of very robust steel, which allows greater pressure to be applied in order to split the heavy and long tile.

Likewise – the larger Masterpiuma Tile Cutters, whilst mounted on the Vertigo support, can be used in the classic horizontal way as shown in the video. At the end it is then demonstrated how easy it is to move by one man.

The objective of this product is to improve the working conditions of the tile layer and at the same time create a tool that can minimize the risk of breaking large format tiles, tiles which are becoming increasingly popular and recommended by designers and architects.

Copyright 2022 Brevetti Montolit S.p.A. - VAT number IT00713300127 - R.E.A. VA151380 - Social Capital fully paid €500.000,00 - Registered office address: Via Turconi 25 – Cantello (VA) - PEC certificata@pec.montolit.it

Digital Marketing by Develed Sagl